Converting biomass materials into valuable fuels and chemicals by microbes is a hot topic in bio-manufacturing. A problem hindering this process is the inefficient co-utilization of pentoses and hexoses.

Many efforts have been made to achieve pentoses and hexoses co-utilization through single strain engineering or consortium engineering. Limited by the low efficiency of pentoses metabolism, however, the target products were always produced at low levels.

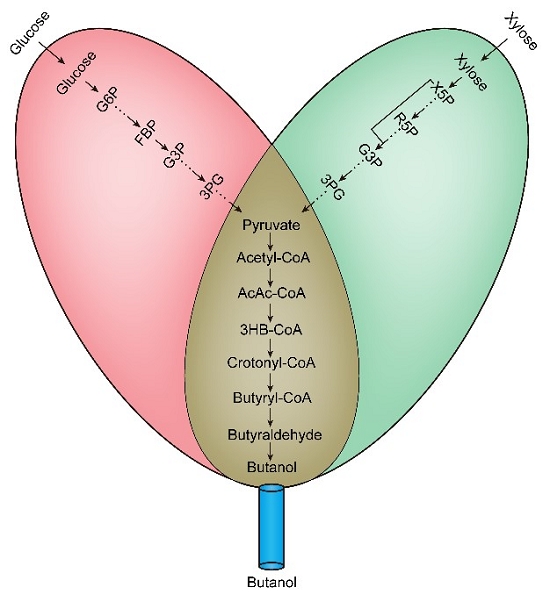

In recent years, synthetic microbiome is rapidly developing benefit from synthetic biology and microbiome project. A research group led by Prof. LI Yin at Institute of Microbiology, Chinese Academy of Sciences designed and developed a new “Y-shaped” synthetic consortium (Figure 1) to achieve efficient pentoses and hexoses co-utilization.

The “Y-shaped” synthetic consortium is composed of two engineering strains originating from the same original strain and producing the same target product. The two “heads” represent the metabolic pathways of pentoses and hexoses, while the same “body” represents the synthetic pathway of target product.

The “Y-shaped” synthetic consortium should have four key features: (1) capable of catabolizing C5 and C6 sugars in rapid and comparable rates; (2) the catabolism of C5 and C6 sugars are orthogonal so they don’t interact with each other; (3) the target metabolites of C5 and C6 catabolism are better to be the same and the catabolism of C5 and C6 sugars are compatible with the production of the target metabolites; (4) the microbial consortium is genetically stable, preferably not containing plasmids or resistance maker, so that the consortium can be stably passaged under industrial conditions.

To test this new concept of “Y-shaped” consortium, researchers took butanol as target product and developed a “Y-shaped” synthetic consortium using systematically engineered Escherichia coli strains. One strain in the consortium is E. coli EB243 capable of producing high titer of butanol from hexose (e.g. glucose), while the other strain is E. coli EB243X with similar butanol producing capacity from pentose (e.g. xylose). In batch fermentation of mixed sugars, this “Y-shaped” synthetic consortium produced ~21 g/L butanol with a yield of 85% of the theoretical value which is the highest one ever reported.

Further analysis indicated efficient simultaneous utilization of sugars mixtures with different ratios of pentose/hexose and different aeration conditions could be achieved by simply adjusting the initial structure of this “Y-shaped” consortium. This further indicated the adaptability and stability of the “Y-shaped” consortium which may be used in industrial production.

This work provides new insights for the study of efficient co-utilization of pentoses and hexoses by synthetic microbiome. It also lays a foundation for further reducing the cost of producing biobutanol.

This work supported by the National Natural Science Foundation of China and the National High Technology Research and Development Program of China was published in Metabolic Engineering.

https://www.sciencedirect.com/science/article/pii/S1096717619302162

Figure 1 Illustration of the “Y-shaped” synthetic consortium (Image by LI Yin’s group)

Contact:

Prof. LI Yin

CAS Key Laboratory of Microbial Physiological and Metabolic Engineering,Institute Of Microbiology,Chinese Academy of Sciences,100101,Beijing, China

E-mail: yli@im.ac.cn